Blast Furnaces need to be pre-heated in order to ensure there is good heat penetration through the fairly thick refractories of the hearth region. By embedding the HAL System around 2 ft. below the refractory's hearth, it is possible to reach temperatures of 100°C and upward, with a furnace temperature of more than 550°C, and ensuring a thorough initial dry-out.

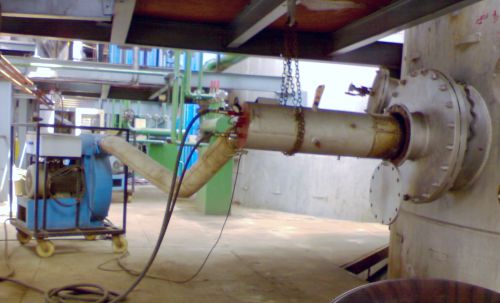

Depending on the size of the furnace, HAL High Velocity Burners are placed at the tuyere level (and by temporarily removing the appropriate number of tuyere stocks). Most often, around 50% of the burners are angled upwards, while the remaining burners fire down the hearth.

Our expertise has led us to occasionally perform a coordinated dry-out of the Stoves, Blast Furnace, Hot Blast Main and Bustle Pipe. The firing up of individual heating cycles is staggered, to ensure that all units are at the appropriate temperature, when the plant operations resume.